What Size Lift For 33 Inch Tires Silverado

For nigh Jeepers, a tire upgrade is the biggest trail performance bang for the buildup dollars. It offers improvements in both vital trail performance parameters, traction, clearance, and just looks absurd. To start, please refer to the Suspension Counselor for more than tips on what tire sizes volition fit on your Jeep. While you lot can go an improvement in operation from even a small size upgrade, the benefits multiply every bit you lot go bigger... within limits. There comes a place, and it varies from Jeep to Jeep, where the cost, complications and compromises accept to be very seriously considered and balanced against your end use of your Jeep.

Your Jeep wheels deport you anywhere you lot want to become, whether you're driving through town or off-road. Taking an off-road trip is exhilarating, but having the right size tires is a necessity. Rough trails full of rocks and debris article of clothing your tires down prematurely, merely 4WD.com offers the high-quality parts you demand to keep having great off-road experiences.

Choose the Correct Tire Size

Nothing excites you more than boiling the balonies while you travel off road. When your tires chunk and you lot need to replace them, choosing the correct size is vital to improving your off-road experience. 4WD.com sells the perfect replacements. Whether yous choose tires that measure 33, 35 or 37 inches, y'all should option a compatible rim. Rims have guidelines as to which tire sizes they can be used with finer. These guidelines ensure that your Jeep wheels perform better when they are off-road.

Pick a Philharmonic

When traveling off-road, yous desire to be able to air-downwards for better control, especially when traveling on rocky terrain. To increase operation, your tire should be compatible with your rim size. 33-inch tires work well with rims that measure 15 or 16 inches in width, while 35-inch tires should simply be used with rims that are at least 17-inches wide. Larger tires require wider rims to maximize the tire profile and ameliorate your Jeep'southward maneuverability. 33-inch tires on xv-inch rims brand a great combination because they give your ride both flexibility and control, vital parts of off-roading.

Store Confidently With Our Cost Guarantee

At 4WD, we are dedicated to helping jeepers find the highest quality parts at the all-time prices. Nosotros volition happily price match and refund the difference if you lot happen to find a better toll inside 90 days of purchasing a Jeep office from the states. Nosotros pride ourselves on providing excellent customer service and quality aftermarket parts. We know that we have the parts you demand to beefiness up your ride, and then don't look any longer. Social club from us today.

Popular searches: jeep wrangler seats, jeep roof rack, jeep wrangler soft top, jeep wrangler center console

Choosing a Tire and Cycle Philharmonic

Every tire has a range of rim sizes that will offer the best performance and clothing. The rim diameter is a given. A 15 inch tire has to go on a 15 inch rim. Period. With regards to width, the tire manufacturer list a range for a given tire. A 12.50-inch wide LT tire, for instance, might show a range of approved rim widths from 8.5-xi inches. Some will bear witness a measuring rim width (MRW), which is the rim size used to obtain the department width specification. A narrower rim volition make the tire narrower and a wider one volition fatten it upwardly a flake. A good dominion-of-thumb is that for every one-half-inch of rim width larger or smaller than the MRW, the section width will modify approximately a quarter inch. This tin be useful in fitting a tire that nearly fits simply rubs a little.

The ideal is to make the rim width equal to the MRW, where the manufacturer designed the tire to run. At to the lowest degree stay inside the recommended width. If you don't, squirrelly treatment and increased wear could effect on the highway. A narrow rim tends to pull the edges of the tread up and away from contact with the route. Too wide tends to make the tread pull upwardly in the centre. On the trail, either of these extremes could brand the tire more vulnerable to rock damage or being rolled off the rim at low trail pressures.

Some Jeepers similar to run at the minimum cease of the width spec to assistance protect the rim on the trail. Others remember the wider end of the spec is better as it lets the tire flex meliorate. This is one of those controversies where both sides are right... as long as the rim is within the recommended width range.

Check out some of top selling bicycle and tire combos to meet what nosotros mean:

Larger Bore Rims

A recent tendency... and a welcome one... is larger diameter 4x4 rims. You can now upgrade from fifteen or 16 inch diameter rims to 17, 18 or 20 inch rims. The selection of tires to fit these wheels is growing rapidly.

The particular advantage from such a tire/wheel combo comes mostly in the street area. A 37 inch tire on a 15 inch rim has a lot of tire profile (10-11 inches) between the contact patch and the rim. Even when aired up, that makes for a squirrelly tire because the tires tends to curlicue and flex when braking or cornering. Twenty-four hours to twenty-four hours, with a careful, clued-in driver, that may be livable... except in unexpected emergency situations. The larger rims reduce that profile while keeping the same overall tire diameter and the issue is better and more than predictable street treatment. Many people think the contour of a 33 inch tire on a fifteen inch rim, approximately viii-9 inches, is the maximum profile for a tire used day to day on the street. If you run a tire bigger than 35 inches in bore, you are most in demand of a 17-xx inch rim.

The downsides are relatively minor and come on the trail side of things. With the reduced air book of the lower profile tire, you lot may not be able to air down quite as much for the trail. About Jeepers with dual-purpose street/trail machines find information technology an easy compromise. The profile of a 33 offers plenty of room for airing downward to go the flex needed for hard 'wheeling. But the well-nigh hardcore Jeepers needs more, and the odds are his rig isn't a daily driver.

Encounter Jeeper's favorite large wheel and tire combos for some inspiration:

Tread Design

This is one of your most critical choices. It volition dictate street and trail performance, influence street fuel economic system and alter the tire article of clothing equation for the better or worse. The master choice involves evaluating your trail traction needs in the places you lot nigh frequently frequent and balancing them against your street driving needs.

Tread design can be broken up into 3 very basic categories, the street tire, the all-terrain and the mudder. Iv if yous desire to include the rockcrawling variations of the mudder. Nosotros won't talk virtually street tires at all, other than to say they do the best on the street if that'south what you demand. In this case, your 4x4 is likely an all-atmospheric condition vehicle and you'd want to cull an all flavor street tire or even a snowfall rated tire.

Mudders and Rock Tires

The more aggressive the tread design, generally, the amend the trail performance. The open tread pattern of a mud or rock tire divides the tread into small blocks, leaving many void areas. In mud this makes for a tire with lots of edges that piece of work more or less like paddles. The void areas are open enough that the mud that collects in them can be thrown out via centrifugal strength, leaving the tread blocks open to supply grip as they rotate dorsum downwards into the goo.

On rocks, the blocks of tread are more than flexible to conform to irregular surfaces and have many biting edges with which to grip the surface. On height of that, the ground pressure on these blocks of tread is high. In some cases, the weight of the Jeep is concentrated on just a few of these tread blocks and are practically "glued" to the rock. What'southward the divergence between a mud and stone tire? Often very niggling if we are talking most radials. Near radial mudders perform very well in rocks. Not then much the bias ply. The specialty rock tires differ from a true mudder in way the tread blocks are staggered and aligned and many times are directional. Oft, the biggest departure is in the composition of the rubber. Dedicated rock tires often use a softer rubber chemical compound to offer improve grip. Grip will be very much ameliorate than a standard composition but treadwear will be very much reduced when used on the street. Some rockcrawling tires also use actress plies in the carcass to resist sidewall damage.

Ambitious tires accept downsides that appear mostly on the street. In the fuel economy department, you lot may notice a small subtract because they create more than rolling resistance.

Treadwear will also be reduced according to how aggressive the tread pattern and the safety compound. They are often noisier equally well, though modernistic tread blueprint has greatly reduced that tendency. Finally, street handling is reduced because of the deep, flexible tread designs. Choose a mudder or rack tire if trail performance is your near important consideration.

All Terrains

"All-Terrain" is a trademarked name used by BFG since the '70s but 1 which has get a generic term for an all-effectually tire that does "OK" in all venues. In that location are more than and less ambitious ATs but if you notice yourself spending most of your time on the street, or in relatively balmy trail situations, the all terrain will deliver better MPG and treadwear than a mudder, while offering better handling to boot. Water ice and snowfall operation (on the street) is ameliorate equally well. With less void expanse, the AT puts a scrap more rubber to the ground than the MT but the tread is more stable and offers more anticipated handling. ATs are also quieter than mudders.

On the trail, the ATs are at their worst in mud but are good to very good everywhere else. The more than open tread AT designs tend to perform better in the dirt and vice versa. The opposite is generally true on the street. Due to improvements in applied science, the more open up AT tread designs can practice much better on the trail than ever before. Tread depth is nevertheless usually less than a mudder, even on the more ambitious ATs, and so they aren't quite as flexible in conforming to irregular surfaces. Most times, an AT will outperform an MT in sand. Few ATs will equal an MT in rocks, yet. Choose an all-terrain if your Jeep gets a substantial amount of street miles or is used in wintertime climates that have snow.

Speaking of snow, in that location are two tire ratings of interest to those in the snowfall chugalug. The kickoff is the sometime "Mud and Snow" rating (Chiliad&S), which was basically the tire manufacturer saying, "Yeah, it'south OK in the snow. Well, obviously, that's open to some interpretation. The more than recent, and useful, rating is '99 up Winter Tire Traction rating. These tires take to run into an actual winter tire operation standard and those that do are allowed to wear a "snowflake on the mountain" symbol. Many all-flavor and some all-terrains conduct this rating.

The Forgotten Tire

Any tire can exist punctured or cutting so a good spare is a vital tool. "Anything that will agree air," is the common cheapskate'south credo. That's probably a workable philosophy on the street, where a few miles volition deport you to a tire shop. On the trail, replacing a grippy-just-deflated tire with a bald spare reduces your traction potential past every bit much as 25 per centum. You then may struggle on the spots you would normally ace. If the bore is different than the other tires, you could encounter unequal and locker bug. An automatic locker goes positively nuts with two different diameter tires and may go bye-bye as a result. Ouch! The all-time tip... have five identical tires and rims. Include the spare into the rotation process and you will be able to significantly extend the life of any set of tires.

Bicycle Choices: Steel vs Alloy

Your two basic bike choices are aluminum alloy or steel. Steel wheels are tough, malleable and relatively inexpensive, but heavy. Cast or forged blend wheels are lighter, usually stronger than steel (especially forged) merely non equally malleable. The malleability attribute come into play when repairing a bent wheel. Alloys are more problematic to repair, though forged units tend to be more forgiving in that regard than bandage.

Jeeper's Favorite Steel Wheels

The weight of the tire and bicycle is the, "Grizzly in the outhouse," when it comes to tire choices. The increased rotational inertia of bigger tires and wheels puts a larger load on your brakes on the street and reduces handling qualities. On the trail, that inertia adds to drivetrain loads and can help break axle parts.

An "boilerplate" 33 inch tire weighs virtually 55 pounds. A stock 225/75-15 tire weighs 28 pounds. Aftermarket steel wheels are usually heavier and stronger than the stock wheels. In averaging a few aftermarket 15x10 inch steel wheels, we'll use 26 pounds as a number versus almost 16 for the stock bicycle. And then, where the stock wheel and tire philharmonic weighed 44 pounds, a 33 on a 15x10 steel is 81 pounds. An "average" bandage alloy bike (forged are a bit lighter) come in at 16 pounds, dropping the upgraded tire and bicycle back down to 71 pounds.

There are two basic types of alloy wheels to consider, forged and bandage. There are likewise modular wheels, which usually consist of a cast center section with a spun aluminum rim. These wheels are style-weak for the trail, so avert them. In the bandage realm, there are depression-pressure cast wheels and counter pressure level, or "vacuum cast," wheels. The latter system results in a stronger bike because fewer impurities are introduced into the casting. Forged wheels are the strongest and lightest because the wheel are made from billet fabric that is rolled or pressed into shape by millions of pounds of pressure. This double forging makes the alloy stronger by tightening it's grain construction.

Beadlocks... Or Not

Hardcore Jeepers that run extremely depression trail tire pressures ofttimes find beadlocks necessary to avoid rolling the tire off the rim. Most beadlocks use a clamped on ring on the outer dewdrop to grip the tire. Others use an inflatable tube within the tire (with a second valve stalk) and some use a spacer that fits betwixt the beads.

Y'all don't see many daily drivers with beadlocks. Part of that is the extra expense and function is the potential bug an owner may see. For a trail rig seldom driven on the street, these problems aren't an effect, but for a daily driven, dual purpose machine, they may be.

The showtime problem to notation with virtually beadlocks is that they are heavier and much harder to get balanced than a standard wheel. Some owners report the clamping band type beadlocks fail at loftier speed, causing sudden deflation and parts flying around the highway. There are a still a few do-it-yourself beadlock kits out there that depend greatly on the skill of the welder/fabricator. Many, if not nearly, beadlock problems can exist traced dorsum to human error, either honest mistakes or inexcusable stupidity.

Conscientious owners study good service from about styles of beadlocks simply, expense aside, the get-go pick is to evaluate your needs. If you are seldom in extreme terrain, seldom aired down to extreme levels and bulldoze your Jeep regularly on the street, why deal with the potential downsides? The inflatable beadlocks and the spacer styles, yet, seem the almost trouble complimentary in a daily commuter state of affairs.

Backspace, Kickoff

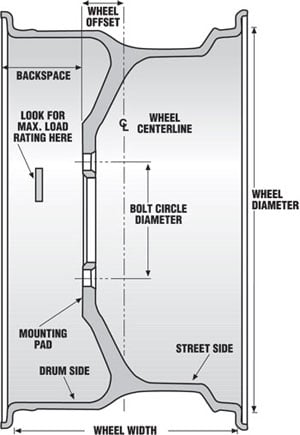

These are two commonly mixed up terms. Backspace is the measurement between the wheel mounting flange and the within edge of the rim. Commencement is the distance from the mounting flange to the exact center of the wheel rim, dewdrop to dewdrop. If the bike centerline is showtime to the exterior (away from the axle), the mounting flange moves to the inside and the bicycle has negative offset. If the centerline is to the within, the wheel flange moves outboard and information technology's called positive offset.

You can determine first by measuring backspace, subtracting that dimension from the rim width and so dividing past two. An 8 inch rim with five.5-inch backspacing has a i.25-inch outset (8.0-v.5=two.five/2=1.25-inches). Think that rim width is technically from bead to bead, not betwixt the outer edges of the rim.

A bigger tire near always comes with an upgrade to a wider rim. Nigh times the actress width will be added as to the inside and outside. That keeps the load on the wheel bearings in the place where the factory intended. A stock 7 inch rim with three-1/ii inch backspace might be replaced by an eight-inch rim with 3-/3/4 inch backspace. Half an inch is added to the within and the other one-half-inch to the outside. How much you can add to the within can become a problem on the front, which has to steer, and so in some cases, more of the extra width is added to the outside edge, for example, an 8-1/2 inch rim with 3-three/4 inch backspace that has an inch added to the outside. Adding to much to the within can go an issue in the front since that is how you steer. In some cases, calculation extra width to the outside border makes sense. For instance, an 8-1/2 inch rim with three-34 inch dorsum infinite will have an inch added to the outside. That keeps the backspace the same but changes the start. Changing the offset a cracking deal in either direction tin cause early on wheel bearing failure and tire wear problems.

Commodities Pattern

Many Jeeps utilize a small-scale 5 on 4.5-inch design. This is fine until you go into large diameter tires. Big and tall tires volition focus a lot of stress and strain over that fairly small surface area which results in some major trouble. It tin appear in the form of broken bike studs, bent wheel flanges, damage to the wheel at the mounting points, among other things. Many experienced hardcore Jeepers think the 35 inch tires are the point where most consider an upgrade to a 5 on 5.5 inch pattern. Tires over 35 inches, especially on a hard worked Jeep, make an upgrade fifty-fifty more necessary. Since hub conversions are generally an aftermarket production that'southward of higher quality than the OE piece, you lot end upward stronger in more ways than but the wheel flange. Eliminating the unit bearing hub plant in XJs, YJs and TJs offers one less weak link to offer upwardly as tribute to the Trail Gods. In some cases, y'all tin include a full-float conversion to the rear axle.

Wheel Spacers/Adapters

A spacer is sometimes necessary to cure minor fitment bug where the culling is prohibitively expensive. A common example is to correct the offset or backspace of a bike and tire that's touching where it shouldn't. When kept within an inch, that's an OK choice. Keep in heed that the bolts belongings the adapter to the hub, which lie unseen under the wheel, can piece of work loose if not properly torqued and regularly checked! Check them a few times after mounting the adapter. Employ spacers as a pocket-size cosmetic device, not so you tin can utilize totally unsuitable wheels. A quality spacer or adapter is normally made of billet aluminum and pretty strong but spacing a wheel out some ridiculous amount is potentially dangerous.

Tech Tip: Finding Street Pressure For Larger Tires

When you increase the tire size, those mill force per unit area recommendations go correct out the window. If your stock 225/75R-15 tire had a 29 psi street rating, the 31x10.fifty yous replaced information technology with might need only 22psi to carry the aforementioned load. You demand a certain volume of air to support a given amount of weight, regardless of the tire size. When y'all have to carry that weight on a small-scale tire with a small internal book, you have to actually pack it in and this increases pressure. Putting the same volume of air into a larger tire, which has more internal volume, creates less pressure just it carries the same weight.

A typical 35 x 12.l-fifteen might show a maximum load rating of 2550 pounds at 35 psi. That ways at 35 psi, those iv tires can deport 10,200 pounds, or 5,100 pounds a pair. Your Jeep weighs iv,500 pounds. How much pressure level practice yous need again? There are many ways of finding the new street pressure for a new set of big tires. All involve some trial and fault. Hither'south one mode.

Step one is to get your Jeep weighed and so you get the forepart and rear weight separately. Load the Jeep equally it's most frequently driven, including a total tank of fuel and you. If yous desire to gene in some dissimilar scenarios, counterbalance information technology light and then with a capacity load. You can get a vehicle weighed in a variety of places, including the local landfill, grain elevators, scrapyards, and truck scales. One time yous have front end and rear weights, you demand to see the manufacturer's load vs inflation charts for the exact tire you lot are using. The tire shop will probably have this data, or can become it from the manufacturer.

First, divide the weight at each end by two to go the private weight on each tire. Accept the per-tire weight and lucifer it to the chart the become the pressure you need for that weight. If the pounds don't match exactly, motion up to the adjacent college pressure. These load vs inflation charts will look like the ane in the sidebar, which is a generic version for some popular tire sizes from the Tire & Rim Clan.

You likely won't weigh side to side but if y'all did, you might find the tire on 1 side is loaded more than than the other. You can recoup by measuring the tire profiles and adding pressure to the depression side until it equals the high ane. Have the measurements on flat footing and on smooth concrete. Front and rear weight, and therefore pressure, will also be different because on end of the vehicle is almost always heavier than the other.

The terminal check is the heat exam. All tires generate a certain amount of heat running down the highway and this heat will enhance the tire pressure somewhat. This is normal. Pressure too low will generate more heat than normal. Check for this by measuring tire pressure after a short, loftier speed run.

Y'all already have your cold pressures. Take a 15 mile run at highway speeds (55mph and up, but within the speed limit), finish and measure the tire pressure. If yous live in a particularly hot area, do this in the morning time before the pavement is blistering hot from the lord's day. If y'all alive in a cold area, do the test in the warmer function of the twenty-four hours or expect for warm weather condition. Pull over in a safe spot and immediately measure the hot tire pressures. They should be well-nigh 10 percentage college than the common cold pressures. If they are college, add together a few pounds of air to each pair (front or rear), let the tires absurd and repeat until y'all get the correct results.

Tire Load vs Inflation Charts*

Each tire is rated differently by manufacturer for maximum load at a given maximum aggrandizement but this chart will give you a general thought of how much weight a given size tire volition bear at a lower inflation.

| Radial Tire Load (lbs.) vs Inflation (PSI) Charts | ||||||

|---|---|---|---|---|---|---|

| Tire Size | 25PSI | 30PSI | 35PSI | 40PSI | 45PSI | 50PSI |

| 30/9.fifty-15LT | 1240 | 1410 | 1570 | 1715 | 1855 | 1990 |

| 33/9.l-15LT | 1565 | 1780 | 1980 | 2170 | 2345 | 2510 |

| 31/x.l-15LT | 1400 | 1595 | 1775 | 1945 | 2100 | 2250 |

| 32/xi.50-15LT | 1575 | 1795 | 1995 | 2185 | 2360 | 2530 |

| 33/12.50-15LT | 1765 | 2000 | 2225 | |||

| 35/12.l-15LT | 2015 | 2295 | 2555 | |||

What Size Lift For 33 Inch Tires Silverado,

Source: https://www.4wd.com/article/content.jsp?childEventId=jeep-advisors-tire-wheel-advisor

Posted by: eastonboung1938.blogspot.com

0 Response to "What Size Lift For 33 Inch Tires Silverado"

Post a Comment